Various milling machine for various tasks

Different milling machines offer a multitude of possibilities for solving various tasks. The use of the individual milling machines we show here!

Anyone who thinks of a milling machine almost automatically has the image of a router in their mind's eye. This circumstance is probably due to the fact that this is might the most popular representative of the tool category "milling", which is all about the machining of workpieces rotates. From wood, to plastic and metal, a variety of materials can be processed.

For the do-it-yourselfer the router is part of the most popular hand-held milling machine, because of its versatility, but you should not forget the biscuit jointer or the wall liner.

The Router

The router is one of the most used tools in many home workshops. Anyone who deals with the topic of "woodworking" and especially the possibilities offered by the router, regularly discovers new application scenarios. A router offers a lot more than just the rounding off edges. Depending on the chosen milling cutter, it can be used in many ways.

Router as a Profile Cutter

In conjunction with a profile cutter, the router is the tool of choice when it comes to handle with edges and sides of a wooden board. Profile cutters are available with a wide variety of profiles, a classic here is clearly the wave profile with which it is possible to freely design skirting boards and other finishing and decorative elements. As an example, a picture frame is called. With a profile cutter with quadrant profile, with a little practice it is even possible to produce round rods and dowels.

Router with groove cutter

In the furniture manufacture the groove cutter is often used, with whom uniformly grooves, for example for drawer bottoms, can be comfortable cut in wood. The groove cutter is also used when working with the milling compass.

Router with V-groove cutter

The V-groove cutter makes it easy to mill V-shaped grooves in wood. This milling machine is used, for example, when lettering should be milled in a wooden board. Also in the production of timber joints, the V-groove cutter can be helpful.

Router as a copy milling

In conjunction with a copy router with ball bearings mounted at either the top or bottom, the router can be used to cut out molds or stencils cleanly. The ball bearing follows the shape in this case and in no time perfect 1:1 copies are made.

Circles with the router

If perfect and clean circular cut-outs are required for a project, for example the construction of loudspeakers, the router with the milling compass is used.

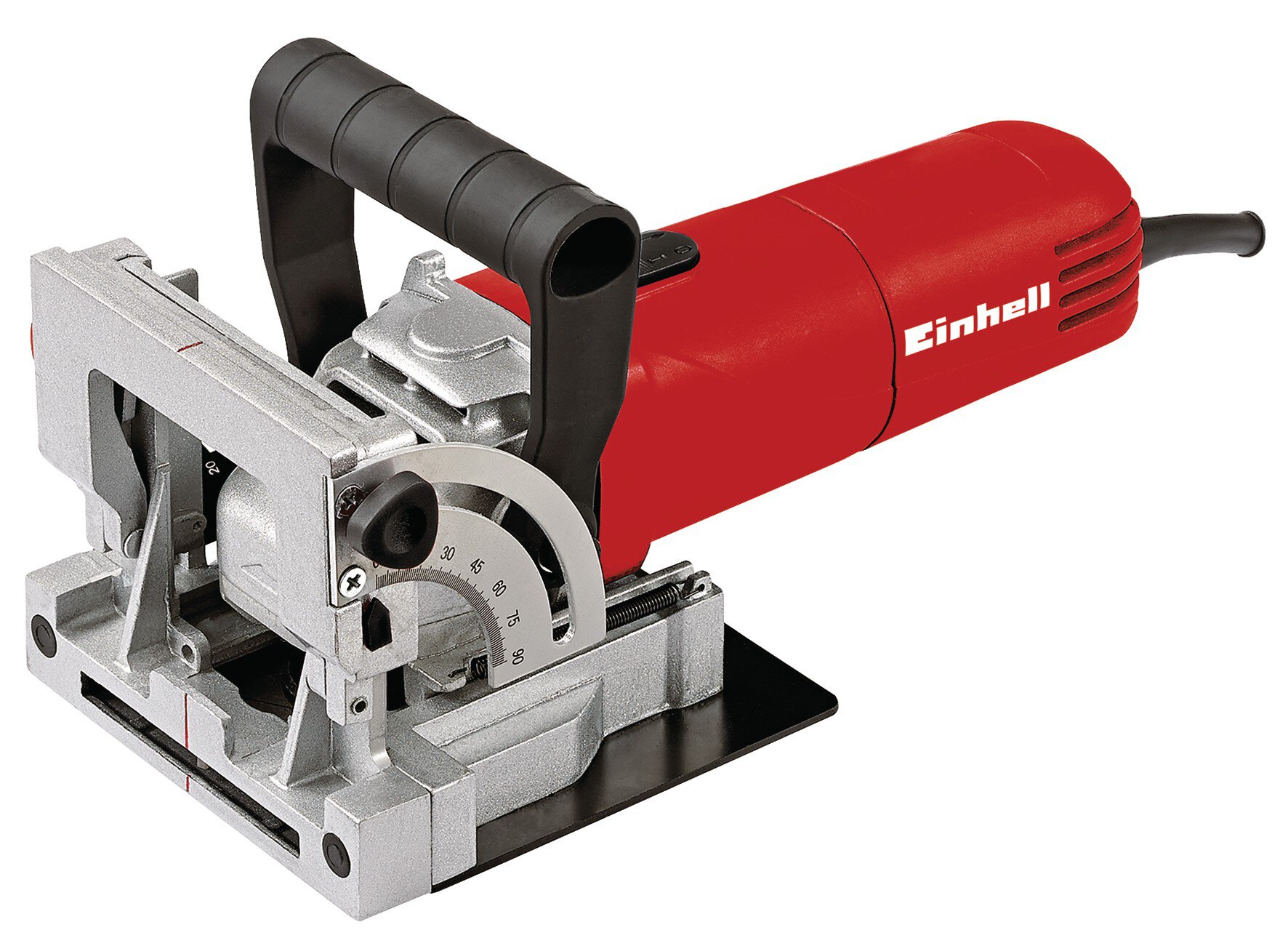

The Biscuit Jointer

The Biscuit Jointer, in contrast to the router, is always used when firm timber joints are required.

With the Biscuit Jointer approximately in furniture manufacture at two opposite wooden boards semi-circular milling are made. Later, the connective lamellas, a wooden platelet, is inserted into this milling and glued. This type of timber joints is extremely stable and in contrast to the connection with classic round dowels, can still be adjusted during gluing. In addition, connective lamellas offer a much larger surface area and thus offer much more stability.

Since connective lamellas tend to swell slightly when they meet with wood glue, the dowels are extremely burly in the wood and can’t slip so easily.

If you want to make your own glued wood, you can align the individual wooden boards with the help of connective lamellas and fix them exactly. Under the pressure of the clamps, the individual parts can no longer slide apart.

Connective lamellas are available in different sizes, to which the bicuit jointer must be adjusted before use. Just like classic round dowels, connective lamellas can be purchased in any well sorted hardware store.

The Wall Liner

At first glance, the wall liner gives the impression of being a mixture of angle grinder and circular saw, but it is also one of the milling machines. In contrast to the biscuit jointer and the router, the wall liner, as the name suggests, is not used in woodworking but when laying cables and pipes in the wall.

The wall liner mills two parallel cuts with its two saw blades into the masonry. The part between the two cuts can then be comfortable knocked off with a rotary hammer or by hand with a hammer and a chisel. Thus, both in the renovation of old buildings as well as new buildings, the pipes find their place in the wall.

As there is a lot of dust when using the wall liner, it is advisable to fix a vacuum cleaner at the designated port.